Founded in 1926, Graco is a world leader in fluid handling systems and components. Graco products move, measure, control, dispense and apply a wide range of fluids and viscous materials used in vehicle lubrication, commercial and industrial settings.

Complete range of Paint sprayers designed for residential and commercial work, line stripers, texture sprayers and accessories.

MR Chemie is a global leader for NDT technology with exports to over 65 countries today. They specialise in offering standard & customised range of solutions for Dye- Penetrant Testing, Magnetic Particle Inspection, UV Technology, Equipment’s and other Accessories.

MR Chemie has successfully pioneered the development of Safe Chemical Technology for NDT. Their Eco Line series has become increasingly popular owing to its Biodegradability, Non Toxic & Non Carcinogenic nature of their products.

They also produce special products for confined area inspections bearing in mind a high safety standard for all our users.

Crack finder / crack detection media and equipment for Non-Destructive Testing (NDT).

Penetrant Testing systems red/white and fluorescent with different sensitivity levels, certified according to EN ISO 3452. Spraying equipment, test lines for PT and activated carbon filters.

Magnetic powder, White contrast paint and additives for Magnetic Particle Inspection (MPI), black/white and fluorescent, for wet and dry testing, ready to use suspensions and concentrates, oil and water based, certified according to EN ISO 9934. Test benches, chain inspection units, high current units, hand yokes and other magnetizing equipment, magnetic field meters and reference test blocks.

UV hand lamps, UV panel lights, UV special lights and UV pocket lamps according to EN ISO 3059, wave length 365 nm, with high UVA power and homogenous illumination.

HYDRAULIC BENDING MACHINES

HYDRAULIC SHEARING MACHINES

ABN stocks and supplies a complete range of welding consumables – Welding Electrodes (MMA) , Welding Wires (MIG / TIG), Sub Arc Wires and Fluxes, Strip Cladding – For Carbon Steel, Stainless Steel, High Nickel Alloys, Aluminium etc.

- MMA Coated Electrodes

- MIG/MAG Cored and Solid Wires

- Submerged Arc Wire/Flux Combination

- TIG and Flame Filler Metal

- Strip Cladding Consumables for Offshore, Power, Shipbuilding

- Flux Cored Wire for Shield Arc Welding

- Covered Arc welding electrodes

- Solid Wire for Gas Tungsten Arc Welding

- Submerged Arc Welding Consumables

- Solid Wire for Gas Metal Arc Welding

- Stainless Steel Coated Electrodes

- Stainless Steel TIG, MIG & SUB-ARC Wire

- Nickel Alloy Coated Electrodes

- Nickel Alloy TIG, MIG & SUB-ARC Wire

- Nickel Alloy Flux Cored Wire

- Titanium & Zirconium TIG Wire

- Bronze & Copper TIG & MIG Wire

- Aluminum TIG & MIG Wire

We are the Official & Authorised Distributors for:

Bavaria Schweisstechnik, Germany (Submerged Arc Welding (SAW) Wires and Fluxes)

Chosun Welding, Korea (Flux Cored Wires, Stainless Steel Electrodes, MIG Wires)

Sandvik, Sweden (Stainless Welding Consumables, Nickel Alloy Welding Consumables)

Exaton, Europe (Stainless Welding Consumables, Nickel Alloy Welding Consumables)

ESAB, Sweden (Complete Range of Welding Consumables)

Voestelpine Bohler Welding, Austria (Complete Range of Welding Consumables)

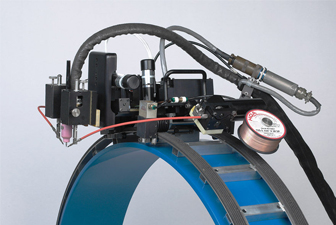

Orbital Welding / Pipe Welding

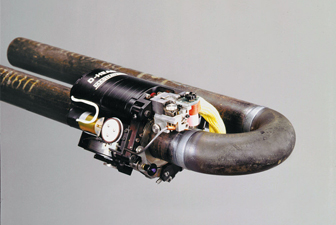

Since 1971, Magnatech has been manufacturing a wide range of systems for orbital tube and pipe welding, as well as for tube-to-tubesheet applications. These innovative products emphasize simplicity, reliability, and ease-of-use.

With this expertise Magnatech started developing pipeline welding systems around 15 years ago. Magnatech International BV introduced the system into the market with great success. The success of the Pipeliner II System is mainly based on reliability and easy-to-use-operation. A high deposition rate producing quality welds with close-to-0% repairs make it even more attractive.

The success is not only equipment related. Our customer approach is looking for partnership. “Partnership is sharing information, that’s what we do – sharing information and providing solutions”.

INDUSTRY

Today’s industry for pipeline welding is in great need of high qualified welders. The average age of a qualified welder worldwide is above 50, which means there will be a substantial shortage in the near future. This development and increasing quality constraints plea for use of automatic pipe welding systems as the consistent quality is produced by the equipment and not by high qualified welders anymore.

Tube-to-Tubesheet Welding

WELD HEADS FOR FUSION AND WIRE FEED GTAW TUBE-TO-TUBESHEET WELDING Magnatech Tubesheet Heads are designed to make tube-to-tube sheet welds with precision and repeatability. All models can be used for fusion welding. The models 424 and 425 provide for filler wire addition – an integral head-mounted feeder is standard.

Three models cover the size range of 10 to 140 mm (0.4 to 5.52″) OD. These weld heads improve productivity by increasing duty cycle, reducing repair rates and producing welds of consistent quality.

Founded in Melbourne Australia, Farley Laserlab is one of the first companies to develop Laser Cutting Systems in the world and one of the oldest machine builders with over 40 years of experience in the industry. Farley Laserlab specialises in developing Laser and Plasma cutting systems and has its presence around the world. The company also has its technical centers in Chicago, USA and Wuhan, China.As a leading manufacturer, Farley Laserlab excels in cutting and welding technology and specialises in the engineering and development of advanced plasma, laser and drilling technologies for a wide variety of applications and industries.

CO2 Laser Cutting Machines – The proven, reliable and affordable laser cutting system, with automatic transfer table and excellent accessibility. The FARLEY•LASERLAB Contour DM Series provides Laser cutting at a repeatable high performance level, with gantry structure, cast Al beam and double side rack and pinion driving system, which supply the machines with high dynamic response speed and 1G acceleration to make sure the corner cutting quality. Exceptional mechanical design, time proven worldwide supported Siemens 840D control system and German made speed reducer and matched skew gear moving structure are some of the many featured that allow for the machines’ single axis maximum running speed up to 120m/min and max. Combined speeds precision with laser cutting at highest accuracy of ± 0.025mm.

Three models cover the size range of 10 to 140 mm (0.4 to 5.52″) OD. These weld heads improve productivity by increasing duty cycle, reducing repair rates and producing welds of consistent quality.

Fiber Laser Cutting Machines – (DF Series) – FARLEY•LASERLAB DF Series Fiber laser cutting machines are the most versatile machine for today’s market – Faster cutting with lower running costs. The DF Series laser cutting machines by FARLEY•LASERLAB adopt a gantry-motion structure, linear guide and screw drive, AC servo motor and drives, dual-side fume extraction system that deliver high performance laser cutting quality by equipping with a world leading IPG fiber laser source. Some of exclusive functions include, Jumping mode, Re-trace Mode and Automatic Edge Detection. Not only is it recommended for Carbon Steel cutting, but also it is excellent for Stainless Steel, Aluminium alloy, Copper and Brass cutting.

Fiber Laser Cutting Machines – (GF Series) – Entry-level solution with compact design. It is reliable, cost efficient and energy efficiency. Adopted with gantry double-drive mobile structure, linear guide rail and screw drive, driven by AC servo motors, GF Series fiber laser cutting machine has bilateral vacuum system and the one-time processing range can reach 3m x 1.5m. It has advanced and reliable design, high integration, more precise controlling and more stable operation. It is widely used for cutting Carbon Steel plates, Stainless Steel plates, Aluminum alloys and Copper alloys.

Pipe Cutting Machines – FARLEY•LASERLAB’s new Pipe Cutting Machine is a milestone advancement in new fiber laser cutting technology. Specifically designed for high volume cutting of tubes and pipes with new enhancements, which allow the system to position and move tubes, and pipes mechanically (eliminating manual handling) to increase speed, precision and productivity. Fully automatic feeding system – regular and rectangular pipes can be integrated into a fully automated feeding process, without human operation.

Oil Pipe Laser Slotting Machines – Oil slotting tube is a device to protect from sand during oil mining. Oil slotting tube can be classified into five types: bridge type oil slotting tube, drilling slotting tube, kerf slotting tube, composited tube, wire-wrapped slotting tube. Oil slotted casing tube is cut by specialized ultra-thin cutting disk and laser beam. There are many certain configurations kerfs with shape of longitudinal or helical straight line on oil slotted casing tube.

Laser Marking Machines – Laser marking is one of the most popular laser processing technologies. Laser marking is local irradiation in substances with high energy laser beam to make it evaporate rapidly and color change by physical or chemical reaction. These markers are permanent and hard to remove.

CNC Plasma & Oxy Fuel Cutting Machines

Plasma cutting utilizes the energy of high temperature plasma arc to partly melt metal, and form the serf through the high-speed plasma momentum. Farley Laser lab delivers excellent cut quality with high quality on small holes and best performance on continuous running. The wide range of solutions from Farley Laser lab for over years makes it suitable for the smallest business to the largest business units.

Waterjet Cutting Machines – A waterjet cutting machine is an industrial tool capable of cutting a wide variety of materials using a very high-pressure jet of water forced through a minute orifice to concentrate high energy at a minimum given area. Waterjet cutting technology is capable of cutting through any material soft or hard. Softer materials could be cut with high-pressure water alone whereas, abrasive garnet (sand) is mixed according to the requirement with water at high pressure to cut through harder materials. ABN International FZCO offers Services and Maintenance of all kind of Waterjet cutting machines.

Coming Soon

Automatic Shot Blasting Machines

Shot Blasting (with carpet conveyors, rotating tables, hook-type devices, etc.), Sandblasting, Shot Peening, Paint Removing and Cleaning Machines through Mechanical Abrasion, for industries such as Foundries, Metal and Carpenter’s workshops, etc. We provide customised machines according to the customers’ technical and economic needs.

Blast Rooms & Paint Booths

Manual blast rooms are specially constructed to suit certain size requirements that are demanded by the customer. They are built with 1 or 2 main doors that is made to access the material. These rooms are equipped with either steel walls or self-bearing panels that are insulated by polyurethane material. The inner walls are supplied with wear-resistant rubber and the floor is fabricated from steel grating.

• Liquid Paint Booths

• Powder Coating Ovens

• Conveyorised Plant

• Powder Coating Booths

• Material Handling Equipments

• Pretreatment Systems

PIPE ROTATORS

PIPE ROTATORS